Disc Check Valve

Price 1500-25000 INR/ Piece

Disc Check Valve Specification

- Material

- Body: Cast Iron / Cast Steel / Stainless Steel; Disc: Stainless Steel / Ductile Iron

- Valve Size

- DN50 to DN600

- Features

- Low pressure drop, high flow capacity, compact design, corrosion resistance

- Control System

- None (automatically operated by flow direction)

- Valve Type

- Wafer Type Check Valve

- Connection Type

- Wafer (fits between flanges)

- Structure

- Dual plate wafer design

- Sealing

- EPDM/Viton/PTFE seat sealing

- Application

- Industrial pipeline systems, steam, water, oil, and gas applications

- Type

- Non-return (Check) Valve

- Power

- Manual (non-powered)

- Pressure

- PN10 / PN16 / PN25

- Media

- Water, oil, air, steam, gas

- Port Size

- 50mm to 600mm

- Temperature

- -10C to 300C

- Disc

- Dual disc, spring assisted

- Pin

- Stainless steel hinge pin

- Maintenance

- Maintenance-free design

- Standard Flange Compatibility

- ANSI, DIN, BS flanges

- Face to Face Standard

- Manufactured as per API 594 / BS 1868

- Operating Principle

- Designed for automatic closure to prevent reverse flow

- End Connection

- Wafer type (sandwiched between flanges)

- Leakage Class

- Class VI (Soft Seat) / Class I (Metal Seat)

- Surface Finish

- Epoxy-coated or shot-blasted

- Flow Direction

- Unidirectional, marked on body

- Spring Material

- Stainless Steel

- Testing Standard

- Hydrostatic tested as per API 598

- Installation Position

- Horizontal or vertical upwards flow

Disc Check Valve Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 20 Pieces Per Day

- Delivery Time

- 1 Week

About Disc Check Valve

Our provided Disc Check Valve is mounted between pipe flanges in any direction and suitable for use on a wide range of fluids for applications in process lines, hot systems, and steam /condensate systems. It is highly demanded in various purposes like high duty cycle applications and on abrasive fluids. Our offered Disc Check Valve is available in various specifications to fulfill the different needs of our valued customers. Our offered Disc Check Valve is known for their unique features like compact design, light in weight, low operating pressures and soft seat options.

Superior Flow Control

This wafer type disc check valve is designed for automatic closure, preventing reverse flow and ensuring unidirectional movement. Its dual plate, spring-assisted structure provides precise sealing and minimal pressure drop even in demanding industrial environments such as steam, oil, and gas pipelines.

Maintenance-Free Reliability

Built with premium materials like cast iron, stainless steel, and ductile iron, the valve features a maintenance-free design. The sturdy hinge pin and epoxy-coated or shot-blasted surface bolster corrosion resistance, making it dependable for years of continuous operation.

Flexible Installation and Easy Compatibility

The valve fits seamlessly between ANSI, DIN, and BS flanges and supports both horizontal and vertical upwards installation positions. Marked flow direction and a compact build simplify installation, while port sizes ranging from DN50 to DN600 suit a wide range of piping requirements.

FAQs of Disc Check Valve:

Q: How is the Disc Check Valve installed within a pipeline system?

A: The valve is installed by sandwiched wafer mounting between compatible flanges (ANSI, DIN, BS standards), with flow direction clearly marked on the body. It supports both horizontal and vertical upwards flow placements, making it versatile for various pipeline layouts.Q: What media can this Disc Check Valve be used with?

A: This valve is suitable for water, steam, oil, air, and gas applications, offering excellent performance and sealing capabilities for a broad spectrum of industrial media.Q: When should I choose a soft seat versus a metal seat leakage class?

A: Select the Class VI (soft seat) for applications where zero leakage is essential, especially with clean fluids. Class I (metal seat) is preferred for higher temperature, abrasive, or less critical leakage environments.Q: Where can this check valve be applied?

A: It is ideal for industrial pipeline systems in processing plants, steam lines, water supply systems, oil and gas utilities, and HVAC applications due to its corrosion resistance and robust flow control features.Q: What is the process for automatic closure in this valve?

A: The dual spring-assisted stainless steel discs automatically close when flow ceases or reverses direction, preventing backflow without manual intervention. This ensures protection and optimal system performance.Q: How does the valve benefit pipeline operation and maintenance?

A: Its maintenance-free design, corrosion resistance, low pressure drop, and high flow capacity collectively reduce downtime, prolong service life, and simplify pipeline management, delivering significant operational savings.Q: Is there any need for electrical or pneumatic power with this valve?

A: No external power source is requiredthe valve operates automatically based on flow direction, making it energy efficient and easy to integrate into both new and existing systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Valve Category

Blow Down Valve

Price 9000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Steam Boiler Blow Down / Draining

Media : Other, Steam, Water

Pressure : Other, Up to 42 kg/cm

Structure : Other, Globe Type Valve

Piston Valve

Price 1500-25000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Industrial pipelines, steam lines, oil and gas plants, chemical process lines

Media : Other, Steam, Water, Oil, Gas, Chemical media

Pressure : Other, Class 150 to Class 600

Structure : Other, Straightthrough piston design

Non Return Valve

Price 1500-50000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Industrial, Water, Oil, Gas, Chemical Processing Systems

Media : Other, Water, Oil, Gas, Steam

Pressure : Other, PN10/PN16 (10 bar/16 bar) or as specified

Structure : Other, Swing or Lift Type

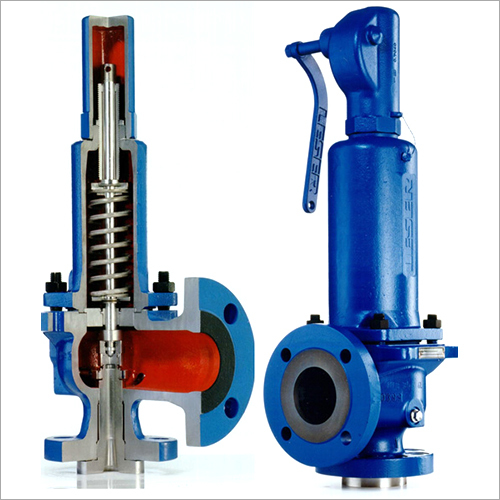

Safety Valve

Price 5000-50000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : STEAM, AIR, GAS

Media : Other

Pressure : High Pressure

Structure : Safety

GST : 27BKYPP6754P1ZQ

|

SAHYADRI INDUSTRIAL TRADERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry